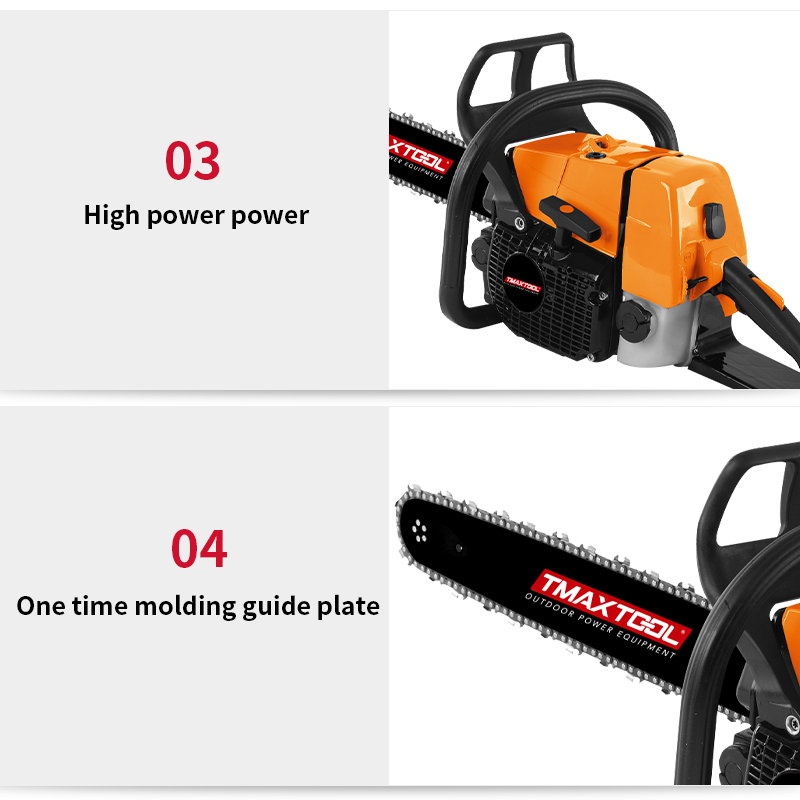

3.2kw 61.5cc MS360 MS361 Petrol Chain Saw Machine

product DETAILS

product description

Introduction to chainsaw sprocket and replacement of chainsaw sprocket

Chain saw sprocket is one of the commonly used chain saw accessories, and its specifications are mainly distinguished by the chain saw and aperture. The commonly used chain saw specifications on the market are: 325, 3/8404; the aperture mainly has two types of large holes (22mm) and small holes (19mm) to match with the passive disc of the clutch cup. Some sprockets of the early models of chain saws were also integrated with the clutch cup, such as the 81 model large machine and the 45 model integrated clutch cup. Due to the loss of the passive disc of the clutch cup is not as large as the sprocket, in order to save the cost of replacing chain saw sprockets, and a chain saw clutch cup passive disc can be matched with multiple chain saw models. Nowadays, most sprockets are integrated with the clutch cup. The cup is formed independently.

The two most common specifications for chainsaw sprockets are small hole sizes of 325-7 and small hole sizes of 3/8-7, and the diameter of trees in domestic forest farms also determines that 325 and 3/8 are the main models for chainsaw chain spacing. Domestic chainsaw sprockets are also relatively affordable in price.

The chainsaw sprocket is usually installed behind the clutch cup, so before replacing the sprocket, the clutch on the clutch cup needs to be removed first. The clutch thread of the chainsaw is a counter toothed nut, and the general clutch will have a clockwise OFF direction arrow printed on it, meaning that clockwise rotation is to loosen and disassemble, while counterclockwise rotation is to lock it. Generally, the clutch and crankshaft are tightened with screw glue when the chainsaw is assembled from the factory, so special tools such as electric or pneumatic wrenches and 24 or 26 diameter three tooth sockets are needed for normal disassembly. 24 or 26 diameter three tooth sockets can be made by oneself, and the separated three edges can be cut off with the 24 or 26 diameter socket, so that they can just get stuck. Hold the clutch. If you don't have the above tools, you can also use tools that are easy to strike and apply force, such as a T-bar sleeve and a hammer, and tap clockwise along the OFF arrow on the clutch. This method is difficult for new hands to remove, requires some patience and strength skills, and it is best to heat a screw area with a hot air gun before tapping. After replacing the sprocket, it is safe to use the tool. Remember to lock the clutch tightly during installation.

Impact Wrench

Impact Wrench

Screwdriver

Screwdriver

Cordless Drill

Cordless Drill

Angle Grinder

Angle Grinder

Polisher

Polisher

Wood Router

Wood Router

Jig Saw

Jig Saw

Hammer Drill

Hammer Drill

Portable Blower

Portable Blower

Orbital Sander

Orbital Sander

Marble Cutter

Marble Cutter

GARDEN TOOLS

GARDEN TOOLS

Battery Chain Saw

Battery Chain Saw

Battery Brush Cutter

Battery Brush Cutter

Battery Hedge Trimmer

Battery Hedge Trimmer

Battery Multi Tool

Battery Multi Tool

Battery Blower

Battery Blower

Batter Pruning Shears

Batter Pruning Shears

Chain Saw

Chain Saw

Brush Cutter

Brush Cutter

Hedge Trimmer

Hedge Trimmer

Multi Tool

Multi Tool

Earth Auger

Earth Auger

Tiller

Tiller

Blower

Blower

4 Stroke Gasoline Engine

4 Stroke Gasoline Engine

Generator

Generator

Water Pump

Water Pump

High Pressure Washer

High Pressure Washer

Wood Cutter

Wood Cutter

4 Stroke Tiller

4 Stroke Tiller

Chain Saw Accessory

Chain Saw Accessory

Brush Cutter Accessory

Brush Cutter Accessory

Earth Auger Accessory

Earth Auger Accessory

Protective Equipment Accessories

Protective Equipment Accessories