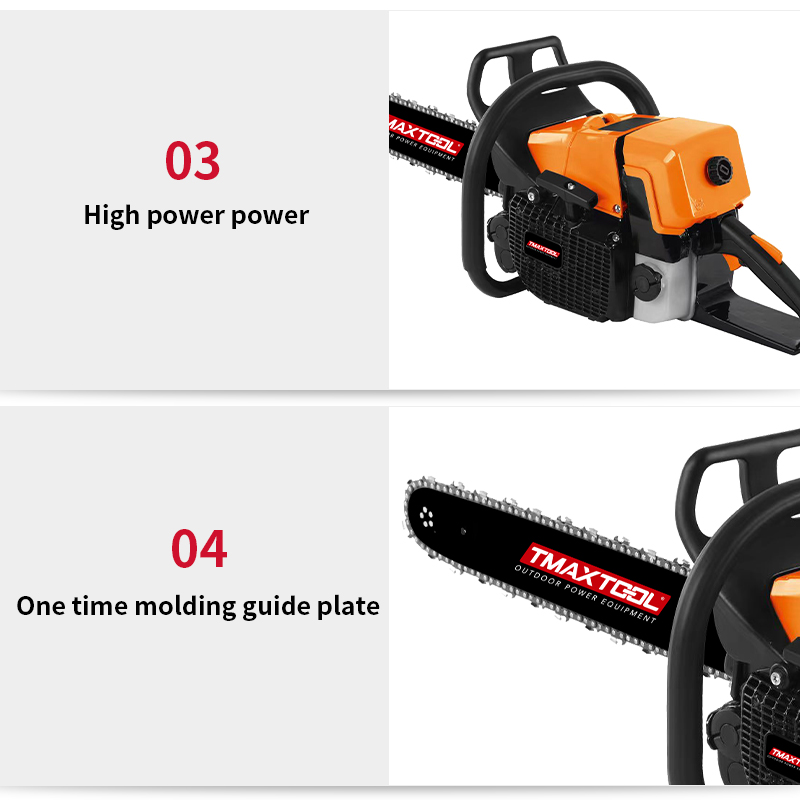

70.7cc 044 MS440 high quality gasoline chain saw

product DETAILS

product description

Chain saws are becoming more and more common in our daily lives, and more and more people are using them. However, many people do not know what to do when problems arise with chainsaws.

1、 The causes and treatment methods of engine oil leakage

When using the engine, oil leakage often occurs, but do you know the reason for the oil leakage? How much do you know about the different locations and treatments of oil spills?

1. Switch oil leakage

The switches include water valve, fuel tank switch, and gasoline switch, etc. Reason and measures: If the ball valve is worn or corroded, the rust between the ball valve and the seat hole should be removed, and a suitable steel ball should be selected as a substitute. If the sealing packing and fastening threads are damaged, the fasteners should be repaired or replaced, and the sealing packing should be replaced. If the conical joint surface is not tight, fine valve sand and engine oil can be used for grinding.

2. Oil leakage from pipe joints

Pipe joints include two categories: conical joints and hollow bolt pipe joints. The conical joint pipe joint includes two ends of the pressure gauge, one end of the gasoline pipe, two ends of the high-pressure oil pipe, and the pipe joint from the fuel coarse filter to the oil pump. If the high-pressure oil pipe joint is worn, deformed, or cracked, it can be sawed off and replaced with a new joint for welding. If the low-pressure oil pipe joint is damaged, the horn mouth can be sawed off and remade. If the thread is damaged, it should be repaired or replaced with a new part. Hollow bolt pipe joints include fuel coarse and fine filters, as well as low-pressure fuel delivery pipe joints for fuel injection pumps. If the gasket is damaged or assembled unevenly, plastic gaskets can be replaced, or a mixed file can be used to level it, or sandpaper can be used to grind it flat. In severe cases, a milling machine can be used to mill it flat. If there are tension marks on the assembly surface of the pipe joint, fine sandpaper or oil stone can be used to smooth the assembly surface and gasket of the joint; If there are impurities on the mating surface, attention should be paid to the cleanliness of the body during assembly, and the fixing bolts of the joint should be tightened evenly.

3. Rotary shaft oil leakage

The rotary shaft includes the clutch lever shaft of the starter gear lever shaft. Reason and measures: If the shaft and hole are worn out, the speed lever shaft and clutch handle shaft of the starter can be cut into sealing ring grooves on the lathe, and corresponding size sealing rubber rings can be installed.

4. Flat joint oil leakage

The flat joint includes two flat surfaces sealed with paper pads, asbestos pads, and cork. Reason and measures: If there are grooves or burrs on the uneven contact surface, a mixed file, fine sandpaper or oilstone should be used to grind it flat according to the unevenness of the contact surface. Large parts can be milled flat with a machine tool. In addition, the assembled gasket must be qualified and cleaned and placed down. If the bolts are loose, each fixing bolt should be tightened.

5. Screw plug oil blockage oil leakage

The oil leakage part of the plug includes conical plug, flat plug, and process plug. Reason and measures: If the oil plug screw is damaged or unqualified, a new part should be replaced; If the screw hole is damaged, the screw hole size can be increased and a new oil plug can be installed; If the conical plug is worn out, it can be changed to a flat plug after tapping with a tap, and then installed with a cushion for reuse.

Impact Wrench

Impact Wrench

Screwdriver

Screwdriver

Cordless Drill

Cordless Drill

Angle Grinder

Angle Grinder

Polisher

Polisher

Wood Router

Wood Router

Jig Saw

Jig Saw

Hammer Drill

Hammer Drill

Portable Blower

Portable Blower

Orbital Sander

Orbital Sander

Marble Cutter

Marble Cutter

GARDEN TOOLS

GARDEN TOOLS

Battery Chain Saw

Battery Chain Saw

Battery Brush Cutter

Battery Brush Cutter

Battery Hedge Trimmer

Battery Hedge Trimmer

Battery Multi Tool

Battery Multi Tool

Battery Blower

Battery Blower

Batter Pruning Shears

Batter Pruning Shears

Chain Saw

Chain Saw

Brush Cutter

Brush Cutter

Hedge Trimmer

Hedge Trimmer

Multi Tool

Multi Tool

Earth Auger

Earth Auger

Tiller

Tiller

Blower

Blower

4 Stroke Gasoline Engine

4 Stroke Gasoline Engine

Generator

Generator

Water Pump

Water Pump

High Pressure Washer

High Pressure Washer

Wood Cutter

Wood Cutter

4 Stroke Tiller

4 Stroke Tiller

Chain Saw Accessory

Chain Saw Accessory

Brush Cutter Accessory

Brush Cutter Accessory

Earth Auger Accessory

Earth Auger Accessory

Protective Equipment Accessories

Protective Equipment Accessories