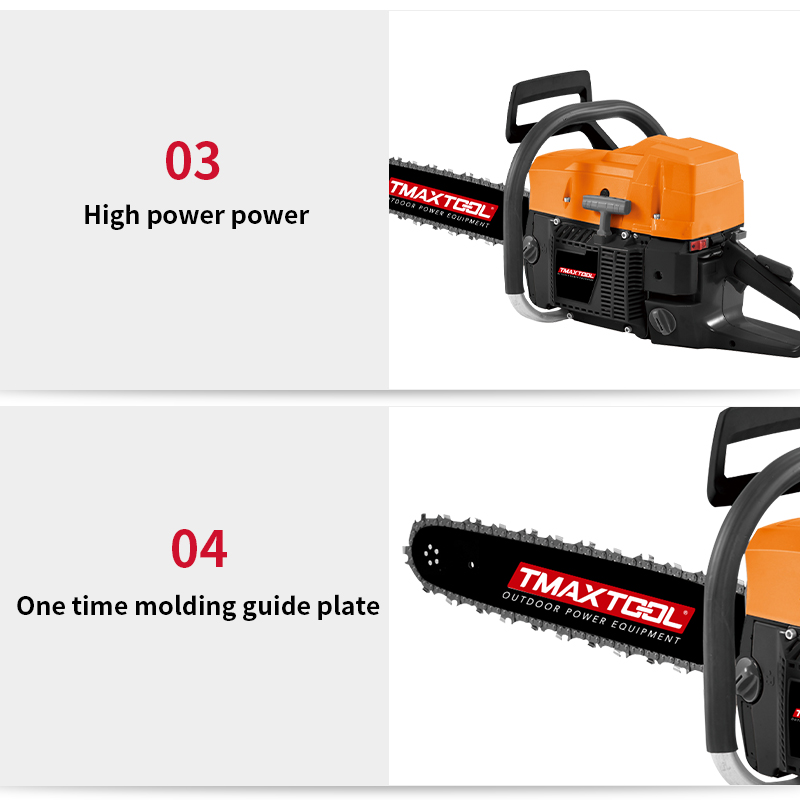

87cc 4.2KW Big Power Chain saw For 288 870

product DETAILS

product description

Any garden tool that has been used for a long time will experience major or minor malfunctions. Whether the faults can be promptly eliminated is directly related to extending its service life and maintaining good working performance. Taking a chainsaw as an example, if you don't understand anything and consult a professional whenever there is a problem, it can be too troublesome. However, if you understand some common faults about chainsaws, you can easily solve simple faults.

Difficulty in starting the chainsaw cooler

When the chainsaw is started, the engine only makes a few loud bangs without any continuous ignition phenomenon. Even after repeated starts, it still remains the same. This is obviously not a problem of low cylinder compression or leakage in the crankcase, nor is it a problem of damage to the spark plugs and high-voltage wires of the ignition system, or insufficient magnetic force of the magneto. This is because of insufficient compression, leakage in the crankcase, leakage of spark plugs and high-voltage wires, permanent demagnetization of magnetic steel, and insufficient magnetic force, making it impossible for the engine to explode. If the fault is in the ignition system, if it is an engine with a contact magneto ignition, the fault is mostly due to loose contact points, burning, oil stains, and the accumulation of oxide layers; It can also be caused by the breakage of the flywheel half moon key and the contact rocker arm spring, as well as the loosening of the movable contact rocker arm. If it is a non-contact magneto, most of it is due to poor contact at the coil connector.

If the fault occurs in the fuel supply system, it is mostly due to moisture in the fuel, air in the fuel pipe, and excessive or rich lubricating oil in the mixed fuel, which can cause the engine to ignite discontinuously when starting the cold engine. Because the specific gravity of water is greater than that of fuel, it deposits at the bottom of the fuel tank. When the engine starts, the fuel in the carburetor can only be supplied for a momentary combustion and explosion. When this water in the fuel tank enters the carburetor or oil pipe, it cuts off the normal supply of fuel, and the engine immediately stops exploding. In addition, excessive lubricating oil in the fuel affects the rapid atomization of the fuel, making it difficult for the mixture to ignite, occasionally igniting, and discontinuous. The fuel in the mixture is too rich, and even if it can be ignited by a strong spark after entering the cylinder, it will quickly "drown" due to too much oil accumulation (that is, the insulation around the center pole of the spark plug and between the side poles are all filled with oil accumulation). If there is too much mixed fuel or too much lubricating oil in the mixed oil, the exhaust gas emitted by the exhaust muffler during the explosion must be black thick smoke.

High temperature shutdown of chainsaw

The common symptom is that after working for a period of time, the engine suddenly stalls and then cannot be pulled. It takes some time to start the fire, and after working for a period of time, this situation occurs again, and it is more frequent in hot weather. The above are common situations where the chainsaw stalls at high temperatures. What should we do in this situation? Firstly, we need to identify the reasons. The common causes and solutions are as follows:

1. Ventilation issues

Mainly due to poor ventilation of the crankcase and plastic parts, which leads to poor ventilation of the carburetor components and causes high-temperature stalling.

Solution: Ventilation. If an air guide cover is added at the magnetic flywheel or the channel between the magnetic flywheel and the carburetor on the crankcase can be opened, the ventilation rate can be increased, or a better ventilated box cover and air filter cover kit can be replaced.

2. Poor exhaust of muffler leading to high temperature

Solution: Clean the muffler or replace it with a muffler with a larger exhaust hole. (Note: having more holes does not necessarily mean arranging them quickly. On the market, double hole large holes are better than three hole small holes.).

3. Low temperature resistance of carburetors

Solution: Add insulation paper pads, ventilate, clean or replace carburetors.

4. The coil/high-voltage package is not resistant to high temperatures

Solution: Replace directly.

5. Three components of cylinder

At least one of the three components, cylinder, piston, and piston ring, is of poor material.

Solution: Replace the chainsaw sleeve cylinder.

6. Oil seals and negative pressure pipes (balance gas pipes) are not resistant to high temperatures

The oil seal and negative pressure pipe (balance gas pipe) are not resistant to high temperatures, resulting in air leakage when the temperature is high.

Solution: Replace the high-quality oil seal and negative pressure pipe (balance air pipe).

Impact Wrench

Impact Wrench

Screwdriver

Screwdriver

Cordless Drill

Cordless Drill

Angle Grinder

Angle Grinder

Polisher

Polisher

Wood Router

Wood Router

Jig Saw

Jig Saw

Hammer Drill

Hammer Drill

Portable Blower

Portable Blower

Orbital Sander

Orbital Sander

Marble Cutter

Marble Cutter

GARDEN TOOLS

GARDEN TOOLS

Battery Chain Saw

Battery Chain Saw

Battery Brush Cutter

Battery Brush Cutter

Battery Hedge Trimmer

Battery Hedge Trimmer

Battery Multi Tool

Battery Multi Tool

Battery Blower

Battery Blower

Batter Pruning Shears

Batter Pruning Shears

Chain Saw

Chain Saw

Brush Cutter

Brush Cutter

Hedge Trimmer

Hedge Trimmer

Multi Tool

Multi Tool

Earth Auger

Earth Auger

Tiller

Tiller

Blower

Blower

4 Stroke Gasoline Engine

4 Stroke Gasoline Engine

Generator

Generator

Water Pump

Water Pump

High Pressure Washer

High Pressure Washer

Wood Cutter

Wood Cutter

4 Stroke Tiller

4 Stroke Tiller

Chain Saw Accessory

Chain Saw Accessory

Brush Cutter Accessory

Brush Cutter Accessory

Earth Auger Accessory

Earth Auger Accessory

Protective Equipment Accessories

Protective Equipment Accessories