Big Petrol Chain Saw ms070 105cc chain saw

product DETAILS

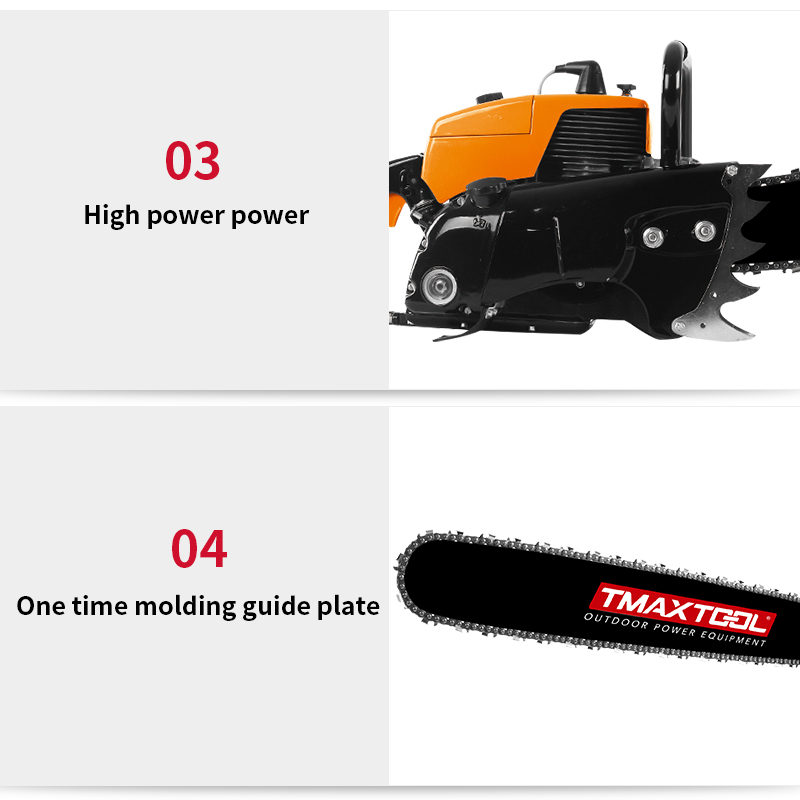

product description

What to do if the chainsaw is weak | Repair method for chainsaw air leakage

The emergence of chainsaws is being used in more and more places, suitable for pruning tree branches in forest firefighting, urban landscaping, highways, lawns and flower beds, agricultural orchards, streets, hospitals, schools, villa areas, parks, etc. More and more families are starting to use chainsaws, but consumers are facing a problem, which is what to do if the chainsaw malfunctions. Today, the editor will talk about the maintenance of chainsaws.

1、 How to solve the problem of a chainsaw being weak?

If the chainsaw is not strong enough, you can check the cylinder and carburetor and lower the speed of the carburetor.

1. Open the safety lock and pull the baffle located in front of the handle back to the handle position. When you hear a "click" sound, it opens. Conversely, pushing forward will lock the chain, and the throttle chain will not move as much as the engine increases.

2. The pitch of the chain teeth is different from that of the sprocket teeth, and it cannot rotate even if it bites across the teeth.

3. The chain teeth and guide rail are too tight and stuck. Can you pull the chain by hand after removing the guide plate and chain from the Koripu chainsaw and placing it on the guide plate.

2、 What's wrong with the chainsaw not starting?

(1) Brake, pull the brake pedal back hard and the car comes to a stop. Pull the front baffle down towards the person's body with peace of mind.

(2) The chain is too tight and needs to be adjusted. Can you pull the chain by hand if it's too tight at the beginning? If it can't be pulled, loosen the chain a bit.

(3) Chain wheel problem, is it due to a lack of oil in the chain? Add some oil to lubricate before starting. The chain and guide plate lack lubricating oil, and in severe cases, they may even get stuck. If such a situation occurs again after adding lubricating oil, it is time to replace the sprocket.

3、 What to do if a chainsaw leaks air?

There are two types of air leakage in chainsaws. One is not serious. The engine speed of the chainsaw increases after starting, producing a continuous and dense knocking sound. The chainsaw runs relatively fast at low throttle, and adjusting the carburetor's fuel supply is ineffective. When cutting wood, increasing the throttle will cause the chainsaw to stall.

Another reason is that when the chainsaw leaks air severely, the engine fails and cannot be restarted, or the chainsaw runs at high speed for a while before the engine immediately stalls. If the air leakage in the crankcase is not severe, when the piston moves upwards, the pressure difference inside the crankcase decreases, and the mixture entering the crankcase and cylinder is very thin. The cylinder is rich in oxygen and burns quickly after ignition. However, the pressure of the gas on the top of the piston after combustion is small. As a result, when the load is added (sawing wood), the oil saw, and the engine shuts down due to insufficient power.

If the crankcase leaks severely, the pressure inside the box is equal to atmospheric pressure, and the chainsaw cannot be started. Quickly identify and eliminate leaks in the crankcase. There are many leaks in the crankcase that are usually invisible to the naked eye. In practice, we use the smoke blowing method to check the leakage area of the crankshaft, which is very simple.

When inspecting, remove the gearbox and flywheel of the chainsaw, push the piston to the top dead center, install the spark plug, take a deep breath of smoke with your mouth, and repair the chainsaw. Use your hand to support the exhaust hole and blow vigorously towards the inlet hole, so as to identify the leaking and smoking area. This inspection method is fast and accurate. If no air leakage is found in the crankcase after repeated blowing of smoke, it is due to the loose fitting of the carburetor and cylinder air inlet, and the fastening screws at the fitting can be tightened. This can solve the problem of air leakage in the chainsaw crankcase!

Impact Wrench

Impact Wrench

Screwdriver

Screwdriver

Cordless Drill

Cordless Drill

Angle Grinder

Angle Grinder

Polisher

Polisher

Wood Router

Wood Router

Jig Saw

Jig Saw

Hammer Drill

Hammer Drill

Portable Blower

Portable Blower

Orbital Sander

Orbital Sander

Marble Cutter

Marble Cutter

GARDEN TOOLS

GARDEN TOOLS

Battery Chain Saw

Battery Chain Saw

Battery Brush Cutter

Battery Brush Cutter

Battery Hedge Trimmer

Battery Hedge Trimmer

Battery Multi Tool

Battery Multi Tool

Battery Blower

Battery Blower

Batter Pruning Shears

Batter Pruning Shears

Chain Saw

Chain Saw

Brush Cutter

Brush Cutter

Hedge Trimmer

Hedge Trimmer

Multi Tool

Multi Tool

Earth Auger

Earth Auger

Tiller

Tiller

Blower

Blower

4 Stroke Gasoline Engine

4 Stroke Gasoline Engine

Generator

Generator

Water Pump

Water Pump

High Pressure Washer

High Pressure Washer

Wood Cutter

Wood Cutter

4 Stroke Tiller

4 Stroke Tiller

Chain Saw Accessory

Chain Saw Accessory

Brush Cutter Accessory

Brush Cutter Accessory

Earth Auger Accessory

Earth Auger Accessory

Protective Equipment Accessories

Protective Equipment Accessories