cordless lithium Electric 16inch hedge trimmer

product DETAILS

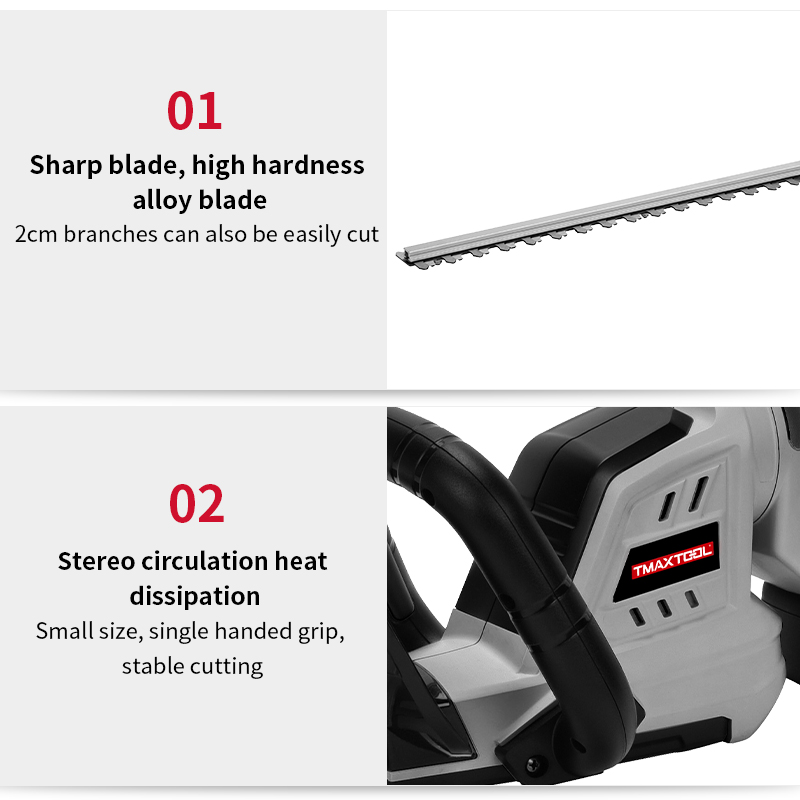

product description

Hedge machine failure and maintenance

Hedge machine may encounter various faults during use, including but not limited to clutch fault, passive disk fault, main transmission gear and eccentric gear wear, connecting rod break, blade pin wear, blade slide wear and so on. For these faults, they can be repaired by replacing damaged parts or adjusting them. For example, a clutch failure may require the addition of a gasket and tightening of the screws, a gear replacement if the main drive gear and eccentric gear wear, a connecting rod replacement if the connecting rod is broken, and a blade pin wear replacement if the blade is replaced. 12

In addition, after long-term use, the hedge machine may have faults such as weak dressing, battery problems, and abnormal ringing. Weak dressing may be due to blade passivation or excessive motor load, battery problems need to take a proper rest and check the battery status, abnormal ringing may be internal parts damaged, need to stop for inspection.

The faults of the hedge machine can be divided into four categories: common faults such as not starting or starting difficulty, insufficient output power, etc.; Minor faults such as loose fasteners and poor electrical contact; Medium failure, such as failure of main mechanism and transmission parts; Major failures, such as serious deformation and fracture of parts.

For the electric hedge machine, if it can not start, should check the fuel, power cord and battery; When the power drops, the blade wear and oil supply should be checked; When leaking oil, check the screws, tubing and oil seal; When the blade rings abnormally, the blade should be replaced; When the vibration is too large, check the blade balance and fuselage screws.

The motor failure of the electric hedge machine includes failure to start and slow speed, and the possible reasons include power failure, motor damage, voltage instability, brush aging, etc. Tool wear is also a common problem, including loss of sharpness and loosening, and solutions include sharpening the tool and adjusting the fastening bolts.

The maintenance of the hedge machine includes regularly checking whether the screws are loose, adjusting the blade clearance, cleaning the blade and filling the oil, and regularly checking the spark plug. The hedge machine that exceeds the service life should be replaced in time.

Impact Wrench

Impact Wrench

Screwdriver

Screwdriver

Cordless Drill

Cordless Drill

Angle Grinder

Angle Grinder

Polisher

Polisher

Wood Router

Wood Router

Jig Saw

Jig Saw

Hammer Drill

Hammer Drill

Portable Blower

Portable Blower

Orbital Sander

Orbital Sander

Marble Cutter

Marble Cutter

GARDEN TOOLS

GARDEN TOOLS

Battery Chain Saw

Battery Chain Saw

Battery Brush Cutter

Battery Brush Cutter

Battery Hedge Trimmer

Battery Hedge Trimmer

Battery Multi Tool

Battery Multi Tool

Battery Blower

Battery Blower

Batter Pruning Shears

Batter Pruning Shears

Chain Saw

Chain Saw

Brush Cutter

Brush Cutter

Hedge Trimmer

Hedge Trimmer

Multi Tool

Multi Tool

Earth Auger

Earth Auger

Tiller

Tiller

Blower

Blower

4 Stroke Gasoline Engine

4 Stroke Gasoline Engine

Generator

Generator

Water Pump

Water Pump

High Pressure Washer

High Pressure Washer

Wood Cutter

Wood Cutter

4 Stroke Tiller

4 Stroke Tiller

Chain Saw Accessory

Chain Saw Accessory

Brush Cutter Accessory

Brush Cutter Accessory

Earth Auger Accessory

Earth Auger Accessory

Protective Equipment Accessories

Protective Equipment Accessories