Wood Chipper Forestry Chaff Cutter Forestry Machinery

product DETAILS

product description

1. Efficient Wood Processing: Wood chippers excel at quickly reducing large volumes of woody material into uniform chips. Highlight their ability to process various sizes and types of wood (branches, logs, stumps) with minimal effort and time, thereby increasing productivity and streamlining operations for forestry, landscaping, or biomass processing businesses.

2.Versatility and Adaptability: Emphasize that wood chippers come in different models and sizes, suitable for both commercial and residential applications. They can handle diverse wood species, from softwoods to hardwoods, and can be easily adjusted to produce chips of varying sizes, catering to specific customer requirements or industry standards.

3.Cost-effectiveness: Wood chipping can help businesses save on disposal costs by transforming waste wood into valuable products like mulch, fuel pellets, or compost. Additionally, investing in a high-quality wood chipper can reduce labor expenses by automating the chipping process and minimizing manual labor.

4.Environmental Sustainability: Promote wood chippers as eco-friendly solutions that contribute to waste reduction and recycling efforts. By converting wood waste into reusable materials, they help minimize landfills, reduce greenhouse gas emissions from decomposing wood, and promote the use of renewable energy sources when chips are used for biomass fuel.

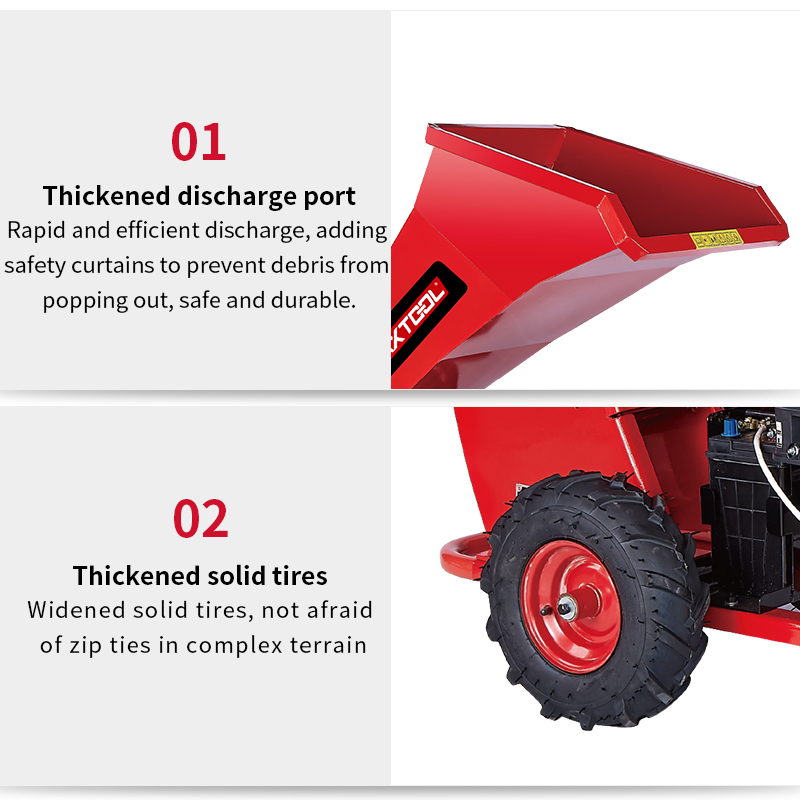

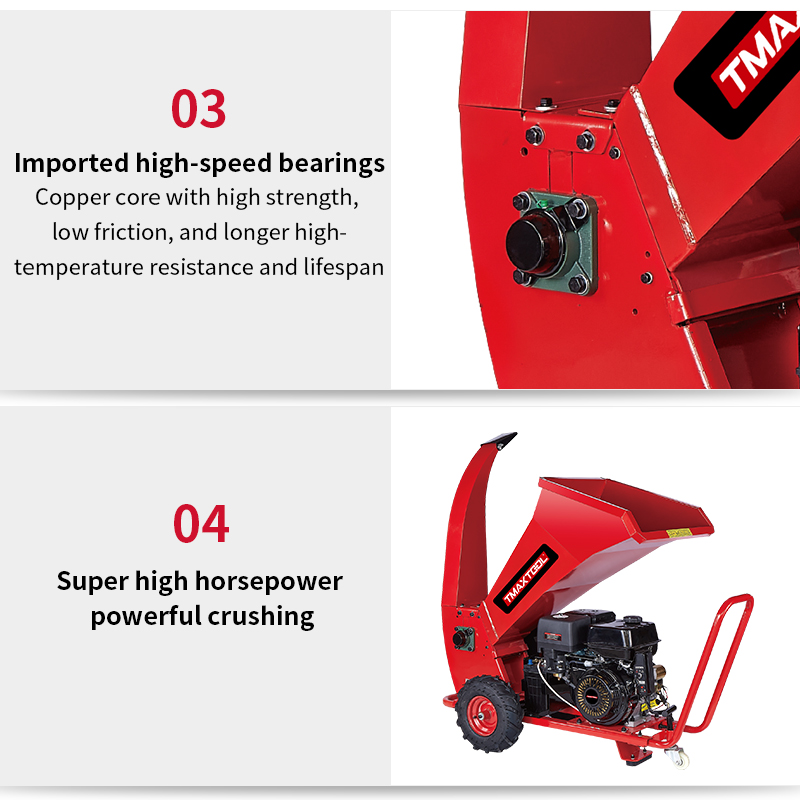

5.Durability and Reliability: Stress the robust construction, heavy-duty components, and high-quality materials used in manufacturing the wood chippers. Highlight features like hardened steel blades, sturdy frames, and reliable engines or motors that ensure long-lasting performance and minimal downtime, even under demanding conditions.

6.Ease of Use and Maintenance: Emphasize user-friendly designs with intuitive controls, easy feed systems, and quick-change blade mechanisms that simplify operation for operators of all skill levels. Also, mention accessible service points, comprehensive operator manuals, and readily available replacement parts, which facilitate routine maintenance and prolong the machine's lifespan.

7.Safety Features: Discuss the integrated safety measures in the wood chipper design, such as emergency stop buttons, feed-stop sensors, protective guards, and automatic shut-off systems, which minimize the risk of accidents and ensure compliance with industry safety standards.

8.Portability and Maneuverability: For mobile wood chippers, highlight their compact size, lightweight design, and options for towing, wheel-mounted, or track configurations, enabling users to easily transport the equipment between job sites or maneuver it within tight spaces.

9. Power Options: Mention the availability of wood chippers with various power sources, such as diesel, gasoline, PTO-driven (for tractor attachment), or electric motors, allowing customers to choose the most suitable option based on their operational needs, budget, and environmental considerations.

Impact Wrench

Impact Wrench

Screwdriver

Screwdriver

Cordless Drill

Cordless Drill

Angle Grinder

Angle Grinder

Polisher

Polisher

Wood Router

Wood Router

Jig Saw

Jig Saw

Hammer Drill

Hammer Drill

Portable Blower

Portable Blower

Orbital Sander

Orbital Sander

Marble Cutter

Marble Cutter

GARDEN TOOLS

GARDEN TOOLS

Battery Chain Saw

Battery Chain Saw

Battery Brush Cutter

Battery Brush Cutter

Battery Hedge Trimmer

Battery Hedge Trimmer

Battery Multi Tool

Battery Multi Tool

Battery Blower

Battery Blower

Batter Pruning Shears

Batter Pruning Shears

Chain Saw

Chain Saw

Brush Cutter

Brush Cutter

Hedge Trimmer

Hedge Trimmer

Multi Tool

Multi Tool

Earth Auger

Earth Auger

Tiller

Tiller

Blower

Blower

4 Stroke Gasoline Engine

4 Stroke Gasoline Engine

Generator

Generator

Water Pump

Water Pump

High Pressure Washer

High Pressure Washer

Wood Cutter

Wood Cutter

4 Stroke Tiller

4 Stroke Tiller

Chain Saw Accessory

Chain Saw Accessory

Brush Cutter Accessory

Brush Cutter Accessory

Earth Auger Accessory

Earth Auger Accessory

Protective Equipment Accessories

Protective Equipment Accessories