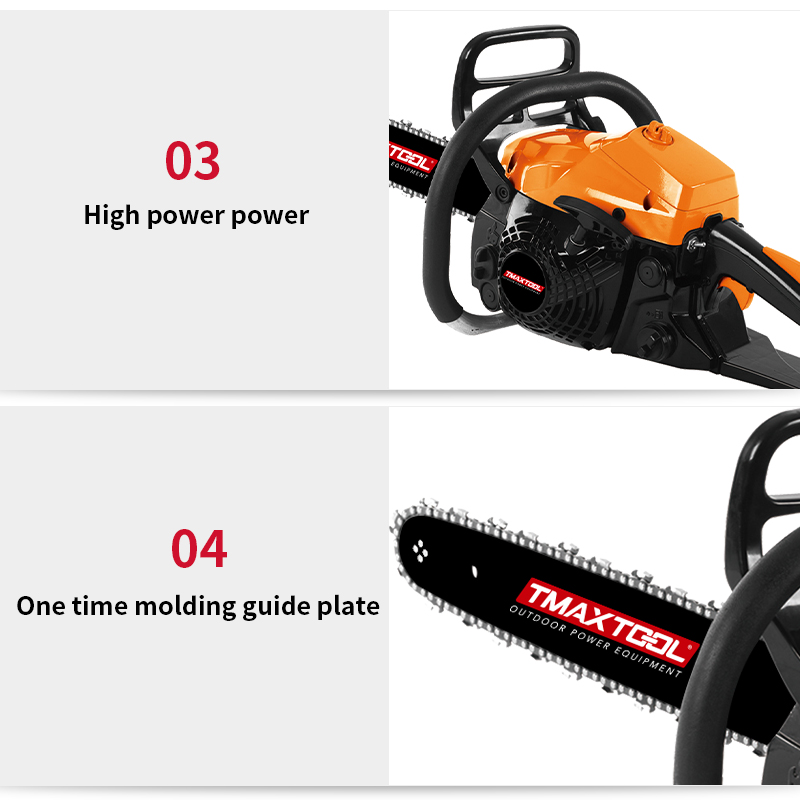

40.2cc Wood Cutting 18" Gasoline Engine Chain Saw

product DETAILS

product description

The chainsaw guide plate and chainsaw chain can be likened to a train and guide rail. The train runs smoothly and accurately to its destination, relying on the support and guidance of the guide rail. Similarly, the chain moves smoothly and rapidly in a straight line, relying on the support and guidance of the guide plate. Without the chainsaw chain, the chainsaw cannot work, and the chain is an indispensable component of the chainsaw.

1、 Composition of saw chains

The saw chain is composed of left cutting teeth, right cutting teeth, middle guide teeth (also known as drive teeth) connecting pieces, and rivets.

2、 What are the specifications of chainsaw chains?

There are mainly three specifications, and the parameters of the saw chain mainly include pitch, thickness of the guide teeth, and shape of the blade teeth.

1. Pitch: The pitch of a saw chain is the distance between three rivets divided by 2, corresponding to the pitch of the sprocket. It includes 1/4, 0.325, small 3/8, large 3/8, and 0.404 (in inches; 1 inch=25.4mm).

2. Middle guide tooth thickness: Corresponding to the width of the guide plate groove, including 0.043, 0.050, 0.058, and 0.063 (in inches; 1 inch=25.4mm).

3. Tooth shape: determines the smoothness of cutting wood, including rounded corners, right angles, and arcs.

3、 Matching of saw chains

Whether the saw chain and chainsaw are matched mainly depends on the chain wheel, guide plate length, guide plate head form, and guide plate guide groove width of the chainsaw. The pitch of the saw chain must be consistent with the chain wheel, guide plate head gear (if there are teeth), the thickness of the middle guide tooth should be consistent with the guide groove on the guide plate, and the length should be consistent with the circumference of the guide plate, the number of sprocket teeth, and the spatial distance between the chain wheel and guide plate before it can be used.

Impact Wrench

Impact Wrench

Screwdriver

Screwdriver

Cordless Drill

Cordless Drill

Angle Grinder

Angle Grinder

Polisher

Polisher

Wood Router

Wood Router

Jig Saw

Jig Saw

Hammer Drill

Hammer Drill

Portable Blower

Portable Blower

Orbital Sander

Orbital Sander

Marble Cutter

Marble Cutter

GARDEN TOOLS

GARDEN TOOLS

Battery Chain Saw

Battery Chain Saw

Battery Brush Cutter

Battery Brush Cutter

Battery Hedge Trimmer

Battery Hedge Trimmer

Battery Multi Tool

Battery Multi Tool

Battery Blower

Battery Blower

Batter Pruning Shears

Batter Pruning Shears

Chain Saw

Chain Saw

Brush Cutter

Brush Cutter

Hedge Trimmer

Hedge Trimmer

Multi Tool

Multi Tool

Earth Auger

Earth Auger

Tiller

Tiller

Blower

Blower

4 Stroke Gasoline Engine

4 Stroke Gasoline Engine

Generator

Generator

Water Pump

Water Pump

High Pressure Washer

High Pressure Washer

Wood Cutter

Wood Cutter

4 Stroke Tiller

4 Stroke Tiller

Chain Saw Accessory

Chain Saw Accessory

Brush Cutter Accessory

Brush Cutter Accessory

Earth Auger Accessory

Earth Auger Accessory

Protective Equipment Accessories

Protective Equipment Accessories