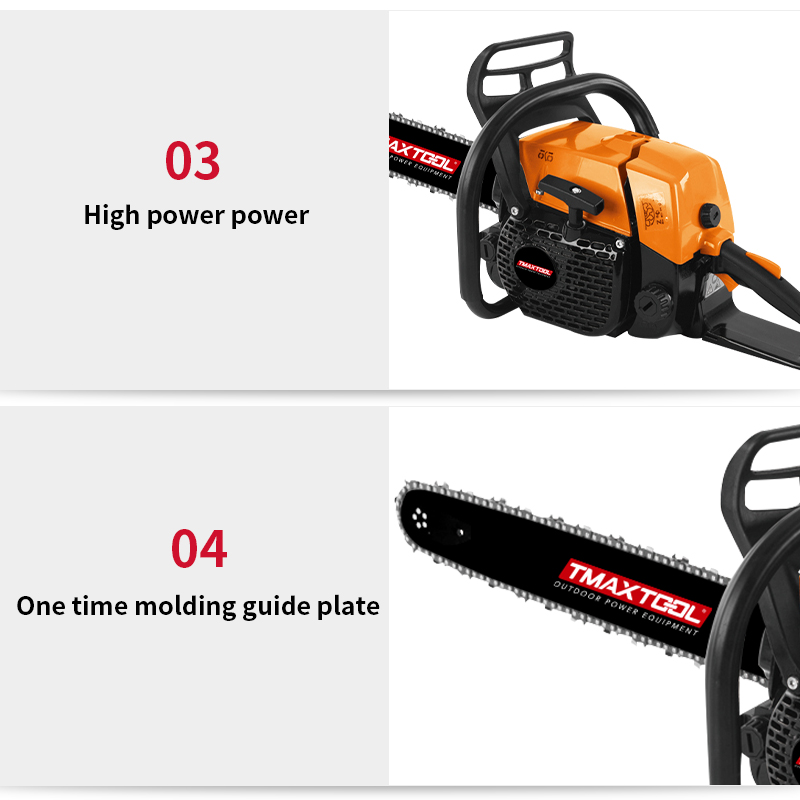

72CC MS380 038 MS381 Gasoline Chain Saw

product DETAILS

product description

Daily maintenance of chainsaws

Chain saws are commonly used logging and landscaping machinery in China, especially in forest areas. They have the advantages of simple structure, convenient use, reliable operation, and durability. The maintenance methods for chainsaws mainly include the following:

1. Daily maintenance:

(1) After finishing daily work, clean the external dust and oil stains of the chainsaw. Clean the air filter screen.

(2) Clean and file the saw chain, store it in lubricating oil, and clean the wood debris and dirt in the saw guide groove.

(3) Remove sawdust and dirt from the fan air filter and heat sink, ensuring smooth cooling air flow.

(4) Check the oil circuit, eliminate oil and gas leaks, and add fuel.

(5) Check the fastening screws of each part and tighten them.

2. 50 hour maintenance:

(1) Complete daily maintenance tasks.

(2) Clean the fuel tank and oil tank with gasoline, check the oil pipes and filters. Release the sediment from the carburetor.

(3) Remove the spark plug and use a copper wire brush to remove carbon deposits, then clean. Check and adjust the spark plug electrode gap. When reinstalling the spark plug, the sealing gasket must be installed properly.

(4) Check the status and clearance of platinum contacts. Contact burning needs to be corrected with a platinum file to maintain flatness and cleanliness. If the gap is not correct, adjustments should be made.

(5) Remove the air duct and cylinder cover, and remove any sawdust or debris from inside and between the heat sinks. Clean the clutch and remove carbon deposits from the muffler.

(6) Add lubricating grease to the reducer and keep it at 30-50 grams regularly. Inject 8-10 grams of engine oil into the oil injection hole behind the drive sprocket.

(7) Remove the dual-mode carburetor, inspect and clean the one-way intake valve. If there is any damage, replace it with a new one.

(8) Use special tools to remove the fan impeller and check if the platinum bottom plate screws are loose.

3. 100 hour maintenance:

(1) Complete the 50 hour maintenance project.

(2) Remove the carburetor and clean it all.

(3) Remove the cylinder and remove carbon deposits from the combustion chamber, piston, piston rings, exhaust holes, and other areas. When removing carbon deposits, do not use a scraper to scrape them off to avoid damaging the metal surface. Check for wear and detachment of the chrome plating layer on the inner wall of the cylinder.

(4) Clean the inside of the crankcase.

(5) Remove the muffler and boil it in water dissolved in caustic soda.

(6) Clean the clutch needle bearing and the needle bearing inside the starter, and add lubricating grease.

Impact Wrench

Impact Wrench

Screwdriver

Screwdriver

Cordless Drill

Cordless Drill

Angle Grinder

Angle Grinder

Polisher

Polisher

Wood Router

Wood Router

Jig Saw

Jig Saw

Hammer Drill

Hammer Drill

Portable Blower

Portable Blower

Orbital Sander

Orbital Sander

Marble Cutter

Marble Cutter

GARDEN TOOLS

GARDEN TOOLS

Battery Chain Saw

Battery Chain Saw

Battery Brush Cutter

Battery Brush Cutter

Battery Hedge Trimmer

Battery Hedge Trimmer

Battery Multi Tool

Battery Multi Tool

Battery Blower

Battery Blower

Batter Pruning Shears

Batter Pruning Shears

Chain Saw

Chain Saw

Brush Cutter

Brush Cutter

Hedge Trimmer

Hedge Trimmer

Multi Tool

Multi Tool

Earth Auger

Earth Auger

Tiller

Tiller

Blower

Blower

4 Stroke Gasoline Engine

4 Stroke Gasoline Engine

Generator

Generator

Water Pump

Water Pump

High Pressure Washer

High Pressure Washer

Wood Cutter

Wood Cutter

4 Stroke Tiller

4 Stroke Tiller

Chain Saw Accessory

Chain Saw Accessory

Brush Cutter Accessory

Brush Cutter Accessory

Earth Auger Accessory

Earth Auger Accessory

Protective Equipment Accessories

Protective Equipment Accessories